Advantages of Spiral Steel Silos

1. Good Overall Performance and Long Service Life.

During the construction process of SRON spiral steel silo, it is completely constructed by special equipment. During the rolling process, the outer wall of the storage silo is bitten into a spiral convex strip that is 5 times the thickness of the material and 30mm-40mm wide, which greatly strengthens the silo body. The bearing capacity of the steel storage silo makes the overall strength, stability and shock resistance of the steel silo better than other silo. In addition, the material of the silo body can be selected according to the requirements of anti-corrosion and grinding strength of the stored materials, and the optimal plate ratio can be selected, so that its normal service life can reach 30-40 years. This far exceeds the service life of other silos.

During the construction process of SRON spiral steel silo, it is completely constructed by special equipment. During the rolling process, the outer wall of the storage silo is bitten into a spiral convex strip that is 5 times the thickness of the material and 30mm-40mm wide, which greatly strengthens the silo body. The bearing capacity of the steel storage silo makes the overall strength, stability and shock resistance of the steel silo better than other silo. In addition, the material of the silo body can be selected according to the requirements of anti-corrosion and grinding strength of the stored materials, and the optimal plate ratio can be selected, so that its normal service life can reach 30-40 years. This far exceeds the service life of other silos.

(1).jpg)

2. Good Airtight Performance and Wide Usage.

Because the steel silo adopts special equipment for rolling silo to bend and bite, it can ensure the quality of any part of the storage silo body in terms of technology, so its sealing is particularly good, and it can store cement, fly ash, slag powder and other powders materials widely used in the building materials industry, such as cement plants silo solution, power plants silo solution, grinding stations.

Because the steel silo adopts special equipment for rolling silo to bend and bite, it can ensure the quality of any part of the storage silo body in terms of technology, so its sealing is particularly good, and it can store cement, fly ash, slag powder and other powders materials widely used in the building materials industry, such as cement plants silo solution, power plants silo solution, grinding stations.

(1).jpg)

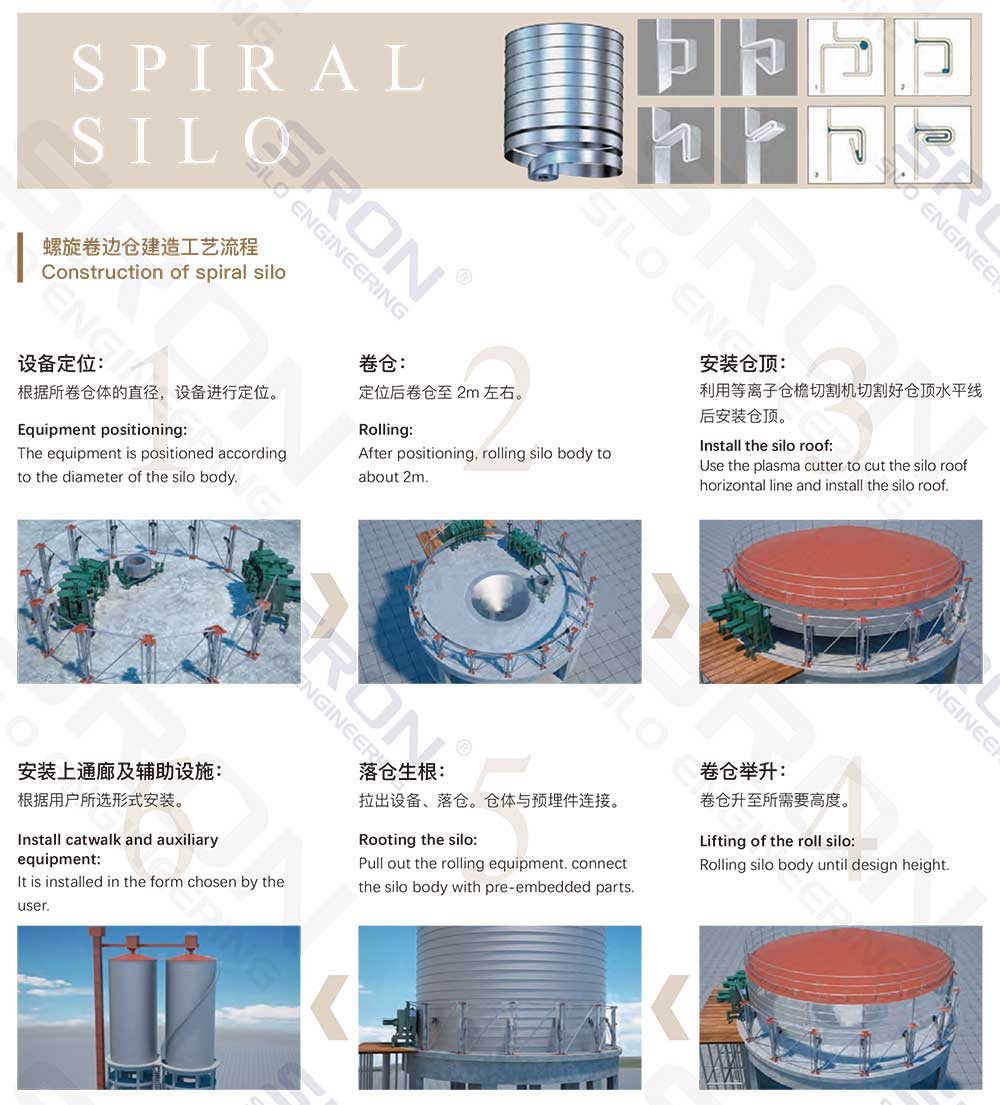

3. Short Construction Period and Low Cost.

The spiral steel silo is constructed on site, and the silo roof is installed on the ground. The forming and bending line speed of the construction equipment can reach 5 m/min, and no scaffolding and other auxiliary facilities are required, so the construction period is extremely short. The spiral steel silo is made of thin steel plates, and the weight is only equivalent to the weight of the steel bars of the reinforced concrete silo of the same capacity, which greatly reduces the cost. In addition, because it can bend and form two different materials inside and outside the cylinder by the double-layer bending method, it can greatly reduce the engineering cost of storing corrosive materials in chemical, environmental protection and other industries.

The spiral steel silo is constructed on site, and the silo roof is installed on the ground. The forming and bending line speed of the construction equipment can reach 5 m/min, and no scaffolding and other auxiliary facilities are required, so the construction period is extremely short. The spiral steel silo is made of thin steel plates, and the weight is only equivalent to the weight of the steel bars of the reinforced concrete silo of the same capacity, which greatly reduces the cost. In addition, because it can bend and form two different materials inside and outside the cylinder by the double-layer bending method, it can greatly reduce the engineering cost of storing corrosive materials in chemical, environmental protection and other industries.

4. The Floor Area is Small and Easy to Manage.

The spiral steel silo is different from other steel silos, and the height and diameter can be arbitrarily selected within a large range. The minimum distance between the two silos is 500 mm, which can make full use of the space and reduce the floor space. The spiral storage steel silo has a high degree of automation, and is equipped with temperature measurement, material level and other equipment, which is very convenient for users to manage.

The spiral steel silo is different from other steel silos, and the height and diameter can be arbitrarily selected within a large range. The minimum distance between the two silos is 500 mm, which can make full use of the space and reduce the floor space. The spiral storage steel silo has a high degree of automation, and is equipped with temperature measurement, material level and other equipment, which is very convenient for users to manage.

.jpg)

5. High Strength.

The continuous spiral undercut of the steel silo is five times the thickness of the base metal, which greatly enhances the load resistance of the steel silo.

6. Small Footprint and Light Weight.

The height and diameter of SRON storage silos can be freely selected within a wide range, and the spacing between steel silos is as small as 50 cm, which can make full use of space. The self-weight of the spiral steel silo is only 1/6 of that of the concrete silo of the same volume, which is the same as the weight of the steel bar of the concrete silo of the same volume, which can greatly reduce the load of the foundation structure and the cost of building the silo.

The continuous spiral undercut of the steel silo is five times the thickness of the base metal, which greatly enhances the load resistance of the steel silo.

6. Small Footprint and Light Weight.

The height and diameter of SRON storage silos can be freely selected within a wide range, and the spacing between steel silos is as small as 50 cm, which can make full use of space. The self-weight of the spiral steel silo is only 1/6 of that of the concrete silo of the same volume, which is the same as the weight of the steel bar of the concrete silo of the same volume, which can greatly reduce the load of the foundation structure and the cost of building the silo.

.jpg)

About Sron Silo Engineering

HENAN SRON SILO ENGINEERING Co., Ltd. is China leading reputable EPC Contractor for bulk materials storage silo project, closed storage yard, and bulk material port handling project for grain silo storage solution etc. SRON has the qualifications of Main Contractor for civil construction projects, Main Contractor for mechanical and electrical projects, and Specialized Contractor for steel structure project. We have the complete qualifications in the field of bulk material storage and transportation in China.

SRON focuses on scientific and technological research, achieving new researching technologies each year. Currently we have 78 patented technology, among which 8 are invention patents.

SRON have built projects in more than 30 countries and regions, including Russia, South Africa, Indonesia, Malaysia, Kenya, Mongolia, Philippines, Peru and so on, with more than 900 sets of steel silos and up to 3 million tons of materials storage capacities, SRON quality and reputation are highly recognized by global users. For more information about Sron Silo Engineering and the Storage silo solution, please contact us or leave your requirements.

HENAN SRON SILO ENGINEERING Co., Ltd. is China leading reputable EPC Contractor for bulk materials storage silo project, closed storage yard, and bulk material port handling project for grain silo storage solution etc. SRON has the qualifications of Main Contractor for civil construction projects, Main Contractor for mechanical and electrical projects, and Specialized Contractor for steel structure project. We have the complete qualifications in the field of bulk material storage and transportation in China.

SRON focuses on scientific and technological research, achieving new researching technologies each year. Currently we have 78 patented technology, among which 8 are invention patents.

SRON have built projects in more than 30 countries and regions, including Russia, South Africa, Indonesia, Malaysia, Kenya, Mongolia, Philippines, Peru and so on, with more than 900 sets of steel silos and up to 3 million tons of materials storage capacities, SRON quality and reputation are highly recognized by global users. For more information about Sron Silo Engineering and the Storage silo solution, please contact us or leave your requirements.