CNSIC Inner Mongolia Fly Ash Silo Project Phase II

Project introduction

This project has a short construction period and a relatively narrow construction area. The two steel silos are located between the owner's cement mill and the main distribution room (about 15 meters wide), and there are conveying pipelines in use (about 20 meters high), which has affected our company’s hoisting operations. Faced with the above situation, our company carefully formulated a hoisting plan, selected appropriate hoisting machinery, and completed the hoisting operation safely and effectively, which was praised by the owner.

The completion of this project is of great significance for improving the owner's fly ash storage capacity, improving the resource utilization of waste, reducing environmental pollution, and lowering costs. In the next step, SRON Company will take this completion acceptance as an opportunity to do our best to complete the finishing work, create a high-quality benchmark project with ingenuity, and contribute to the high-quality development of the bulk material storage and transportation field.

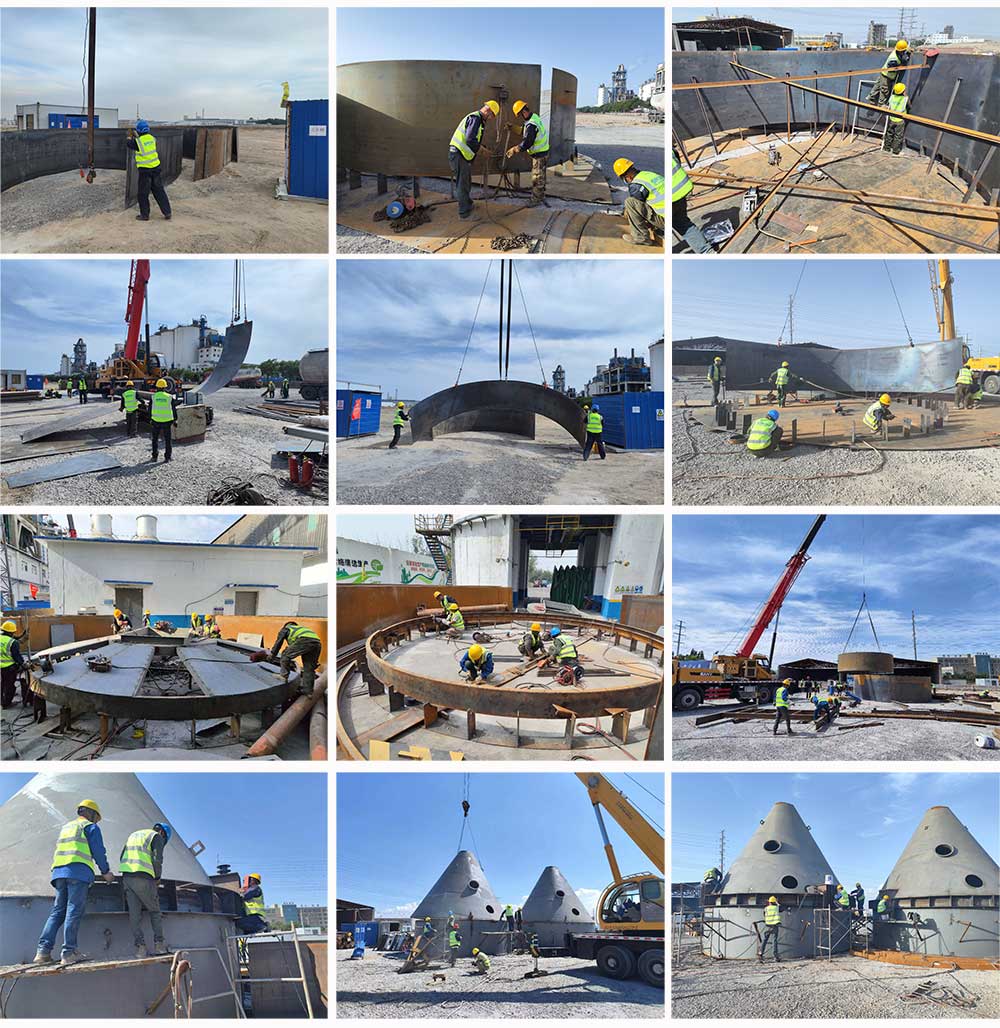

Overview of Construction Process:

After The Materials Arrive At The Construction Site, They Are Sorted And Organized

Project Start and Project Construction Safety Meeting;

Construction Project Site;

Steel Silo Hoisting;

Project Successful Completion

This project has a short construction period and a relatively narrow construction area. The two steel silos are located between the owner's cement mill and the main distribution room (about 15 meters wide), and there are conveying pipelines in use (about 20 meters high), which has affected our company’s hoisting operations. Faced with the above situation, our company carefully formulated a hoisting plan, selected appropriate hoisting machinery, and completed the hoisting operation safely and effectively, which was praised by the owner.

The completion of this project is of great significance for improving the owner's fly ash storage capacity, improving the resource utilization of waste, reducing environmental pollution, and lowering costs. In the next step, SRON Company will take this completion acceptance as an opportunity to do our best to complete the finishing work, create a high-quality benchmark project with ingenuity, and contribute to the high-quality development of the bulk material storage and transportation field.

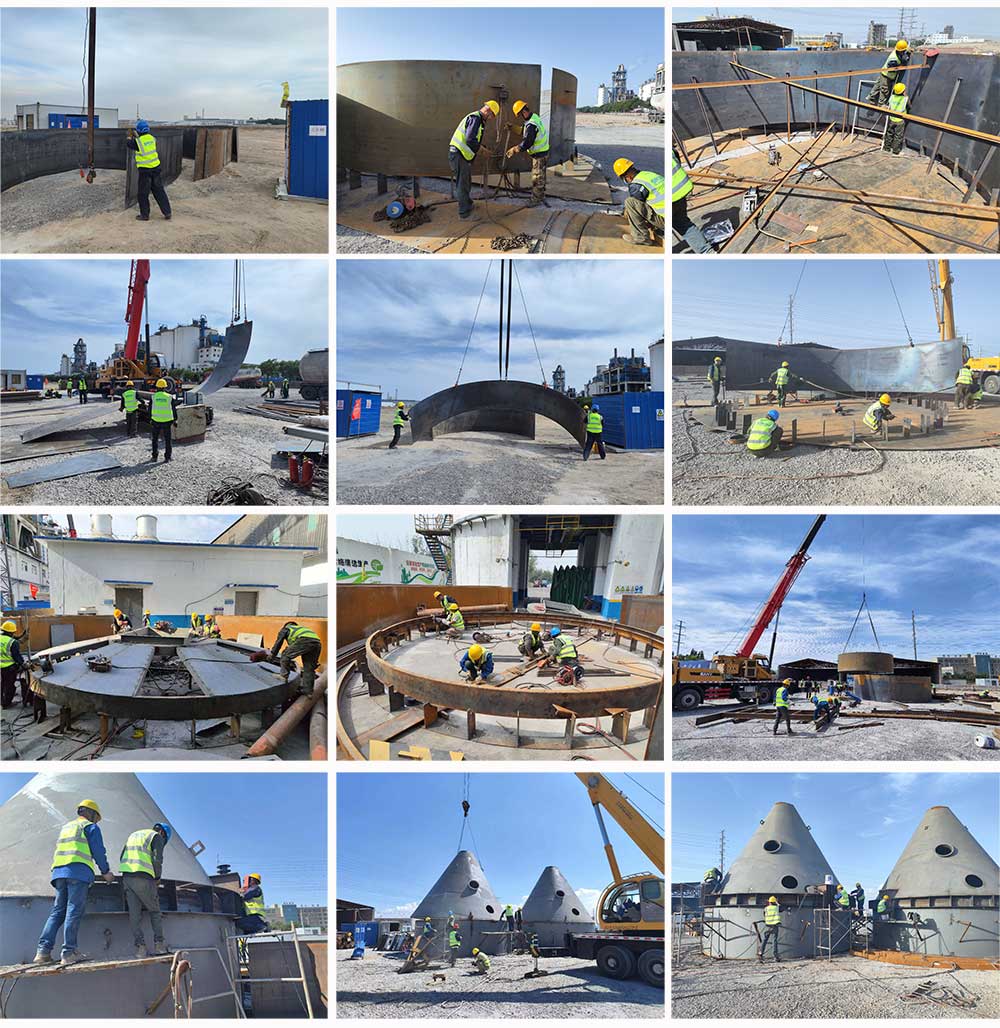

Overview of Construction Process:

After The Materials Arrive At The Construction Site, They Are Sorted And Organized

Project Start and Project Construction Safety Meeting;

Construction Project Site;

Steel Silo Hoisting;

Project Successful Completion

Project Overview

-

Material: Fly Ash

-

Silo Type: Welded Steel Silo

-

Reserves: 1000m³

.jpg)