Dynamic Metering System for Silo Storage System

Project introduction

Dynamic metering system is a system for accurately weighing and controlling material quantity in continuous production process. It is also a necessary equipment in the mixing system.

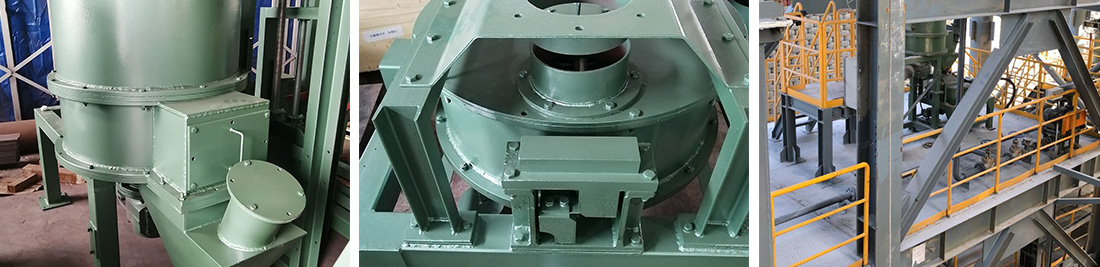

It is applied in the POSCO slag cement mixing system contracted by our company.

Process flow

The byproduct -- slag of POSCO iron making factory is ground by the mill to a certain particle size and then sent to 1000t slag silo for temporary storage. The temporary storage silo has the function of bulk distribution that materials can be sold in bulk or transported into mixing buffer silo through conveying equipment and hoist. A rotor scale is equipped at the bottom of the buffer silo, which can quantitatively feed different kinds of materials into the mixer. After being mixed, materials are loaded and distributed through the bulk loading system.

Project advantages

1.Unique stable flow structure, no arching, stable discharging speed.

2.It is suitable for continuous measurement and batching of powdery materials in various industrial production environments.

3.It is widely used in building materials, metallurgy, electric power, chemical and other industries for powdery materials metering.

Equipment configuration

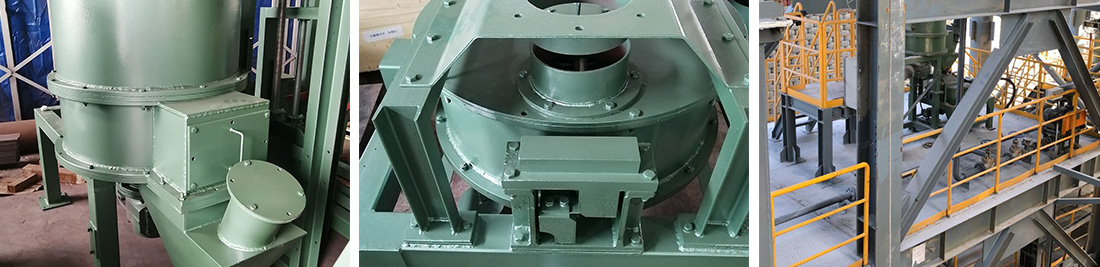

Rotor constant feeder

Dynamic metering system is a system for accurately weighing and controlling material quantity in continuous production process. It is also a necessary equipment in the mixing system.

It is applied in the POSCO slag cement mixing system contracted by our company.

Process flow

The byproduct -- slag of POSCO iron making factory is ground by the mill to a certain particle size and then sent to 1000t slag silo for temporary storage. The temporary storage silo has the function of bulk distribution that materials can be sold in bulk or transported into mixing buffer silo through conveying equipment and hoist. A rotor scale is equipped at the bottom of the buffer silo, which can quantitatively feed different kinds of materials into the mixer. After being mixed, materials are loaded and distributed through the bulk loading system.

Project advantages

1.Unique stable flow structure, no arching, stable discharging speed.

2.It is suitable for continuous measurement and batching of powdery materials in various industrial production environments.

3.It is widely used in building materials, metallurgy, electric power, chemical and other industries for powdery materials metering.

Equipment configuration

Rotor constant feeder

Project overview

-

Materials: Slag Powder Cement

-

Reserves: Slag (1000T) / Cement (3000T)

-

Silo Type: Spiral Silo

-

Technology: Dynamic Metering