Introduction

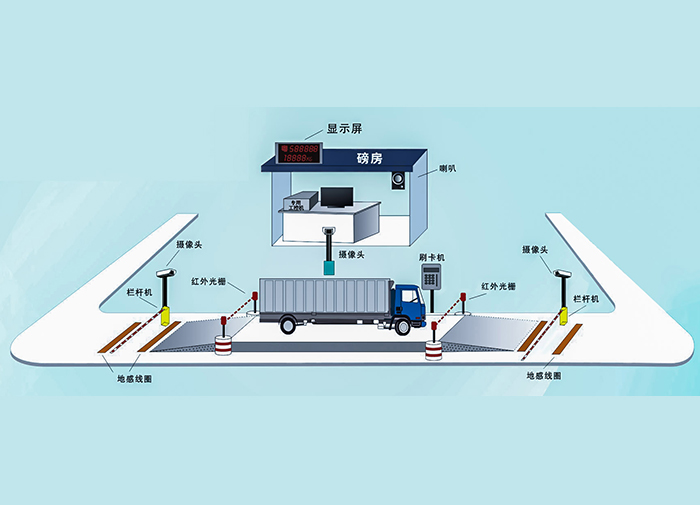

Unattended intelligent loading and weighing system integrates remote recognition system, automatic recognition system, automatic voice command system, instant weighing image capturing system, traffic signal control system, infrared control system, gate control system and remote monitoring system.

System composition: RFID radio frequency card system, road gates, traffic lights, LED large screen display system, video monitoring system, voice intercom system, remote printing system, remote control cheating device and other components.

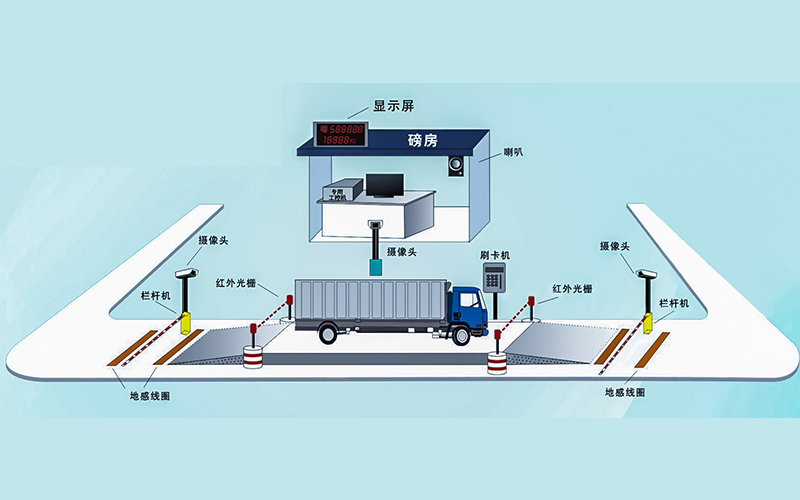

SRON unattended intelligent weighing system adopts 5G intelligent storage and transportation system. Based on 5G big data acquisition and data cloud, and combined with edge computing and cloud computing, it can realize intelligent management of bulk material storage and transportation and digital operation of systems. SRON has established a global silo digital operation center to provide customers with value-added services such as material management, equipment management and energy management.

System composition: RFID radio frequency card system, road gates, traffic lights, LED large screen display system, video monitoring system, voice intercom system, remote printing system, remote control cheating device and other components.

SRON unattended intelligent weighing system adopts 5G intelligent storage and transportation system. Based on 5G big data acquisition and data cloud, and combined with edge computing and cloud computing, it can realize intelligent management of bulk material storage and transportation and digital operation of systems. SRON has established a global silo digital operation center to provide customers with value-added services such as material management, equipment management and energy management.

.jpg)