Introduction

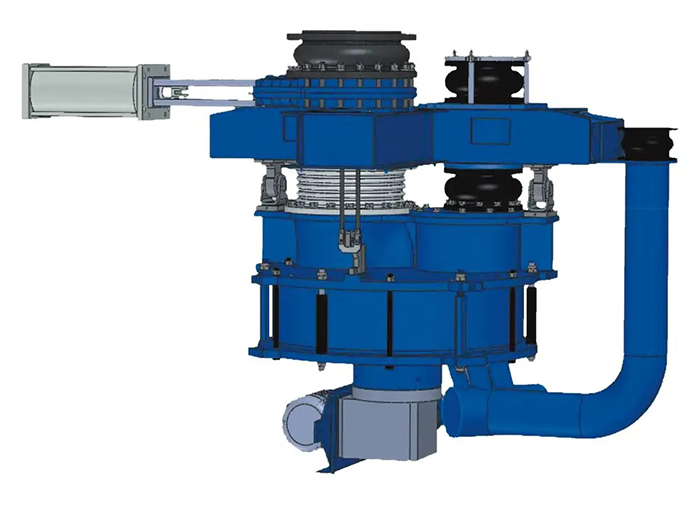

The powder material is fed into ring balance rotor scale by rotor feeder, the rotor scale impeller rotates, so that the material flows evenly in the half circumference from the feed port to the discharge port. Because the scale adopts the balance structure, at this time there is material on one side of the disk-shaped scale, while the other half has no material, so the scale loses balance, and the weight of the material is detected by weighing sensor and sent to control instrument. At the same time, the detected speed signal is sent to the instrument, and the instantaneous flow rate and cumulative amount are obtained after processing. The flow rate can be adjusted by controlling the feeding speed.

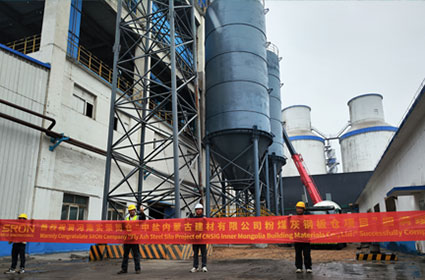

It is widely used in building materials, metallurgy, electric power, chemical industry, coal, mining, port and other industries for quantitative feeding.

It is widely used in building materials, metallurgy, electric power, chemical industry, coal, mining, port and other industries for quantitative feeding.