Introduction

Fly ash is produced due to power generation in power plants, and its production capacity is huge. In the past, fly ash is disposed mainly through the way of landfill, which not only cause pollution on local environment, but also is a waste of fly ash resources.

Grade II fly ash – process progress of fly ash separation

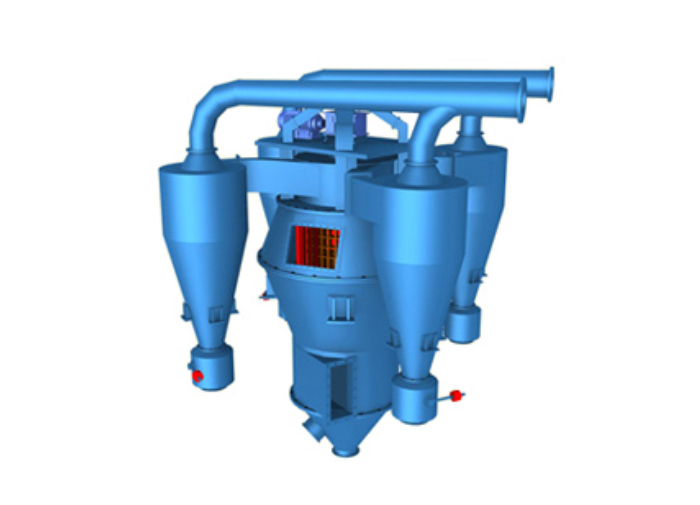

The fly ash stored in raw ash silo is discharged into air chute through silo bottom unloading device. After being lifted by a bucket elevator, it enters a separator for separation. Under the action of the separator, the fly ash of different particle sizes is separated. The separated coarse fly ash is transported to a coarse ash silo through air chute and bucket elevator. The separated fine fly ash is transported to a fine ash silo through air chute and bucket elevator, and the fine ash collected by dust collector is also sent to the fine ash silo.

Grade I fly ash -- fly ash separation + grinding process progress

The metered raw ash is conveyed to the elevator at mill tail and fed into the high-efficiency powder separator through the elevator together with the milled fly ash for separation. The qualified fine powder is collected in the bag filter with air flow, and the collected fine powder is the finished product; it will be transported to a large fine ash storage silo through conveying chute, and screw pump; the coarse powder is sent back to ball mill by the air conveying chute to continue grinding, and the material after grinding is sent to the powder separator by the elevator at mill tail for re-separating.

Grade II fly ash – process progress of fly ash separation

The fly ash stored in raw ash silo is discharged into air chute through silo bottom unloading device. After being lifted by a bucket elevator, it enters a separator for separation. Under the action of the separator, the fly ash of different particle sizes is separated. The separated coarse fly ash is transported to a coarse ash silo through air chute and bucket elevator. The separated fine fly ash is transported to a fine ash silo through air chute and bucket elevator, and the fine ash collected by dust collector is also sent to the fine ash silo.

Grade I fly ash -- fly ash separation + grinding process progress

The metered raw ash is conveyed to the elevator at mill tail and fed into the high-efficiency powder separator through the elevator together with the milled fly ash for separation. The qualified fine powder is collected in the bag filter with air flow, and the collected fine powder is the finished product; it will be transported to a large fine ash storage silo through conveying chute, and screw pump; the coarse powder is sent back to ball mill by the air conveying chute to continue grinding, and the material after grinding is sent to the powder separator by the elevator at mill tail for re-separating.

.jpg)