Introduction

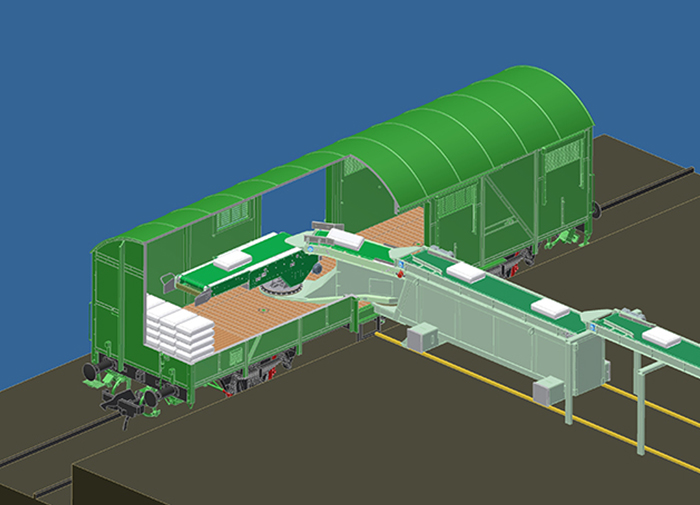

The movement and operation of mobile bagged cement truck loader are convenient in any situation. Especially in the situation that there is no loading and unloading platform, it is convenient and fast for loading and unloading. The inclination section automatically adjusts the height, and the front retractable roller table can freely adjust the length in the horizontal state, making the conveying operation more flexible. At the same time, it can be widely used in fertilizer, food and other industries, for bagged packaging products delivery and loading operations.

The selection of longitudinal moving distance of mobile bagged cement truck loader, namely loader travel distance, should be based on installed truck type. Generally, the length of a truck carriage is 7~12m, so 7~12m of longitudinal moving distance of a truck loader can satisfy requirements.

It can save the loading labor, improve the loading efficiency, and reduce bag breaking in the process of handling, loading and unloading.

The selection of longitudinal moving distance of mobile bagged cement truck loader, namely loader travel distance, should be based on installed truck type. Generally, the length of a truck carriage is 7~12m, so 7~12m of longitudinal moving distance of a truck loader can satisfy requirements.

It can save the loading labor, improve the loading efficiency, and reduce bag breaking in the process of handling, loading and unloading.

.jpg)