Introduction

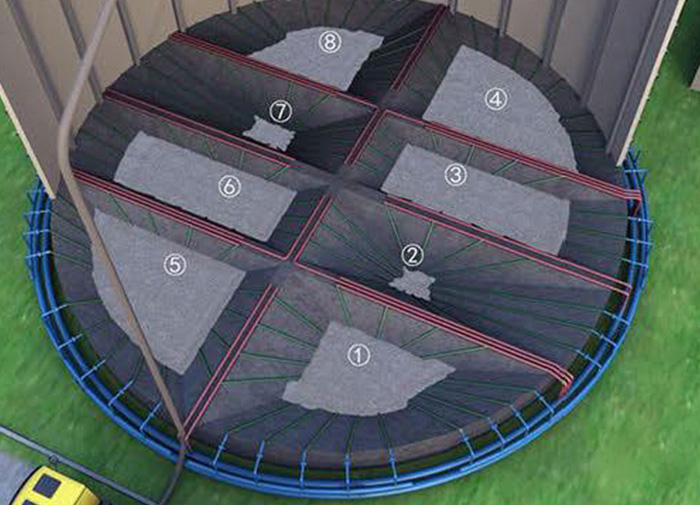

In order to ensure smooth blanking and material homogenization, there is a gasification device at the bottom of the steel silo. Air supply of steel silo is completed by Roots fan. Silo bottom is conical, inclined to the central chamber, and it is divided into 6~14 aeration areas, full of aeration air boxes, which will be opened symmetrically in turn when unloading to make the material flow into pressure-relief cone. The material entering pressure-relief cone becomes activated material after being inflated and stirred, which has good fluidity, so that the material can be smoothly transported into the discharging device distribution box, then discharging operation is completed.