Introduction

Ⅰ.Full-cone gravity discharge

Taking use of the large angle and height of the cone to make the material flow out naturally by gravity.

Advantages: the material flows out smoothly, and there is almost no residuum in the silo; the process is simple and easy to operate, no auxiliary discharge equipment is needed; fully making use of silo capacity without loss of storage capacity, and cone effectively increases silo capacity; the use of steel supports shorten construction period.

Half-cone gravity discharge

Large-diameter silo can adopt half-cone gravity discharge method to balance the discharge effect and construction cost.

Advantages: There is almost no residuum in the silo; no auxiliary discharge equipment is needed; the silo foundation is lower than the full-cone silo.

Ⅱ.Vibration discharge

Vibration discharge system vibrates the cone through the vibration motor so that the material is separated from the cone, and accelerates material flow to make material be discharged smoothly under gravity.

Advantages

1. The entire dischager cone vibrates to realize uniform vibration and discharging. and complete discharging of bulk materials;

2. All parts of the discharger which are in contact with the product can provide a stable material flow;

3. Low maintenance cost.

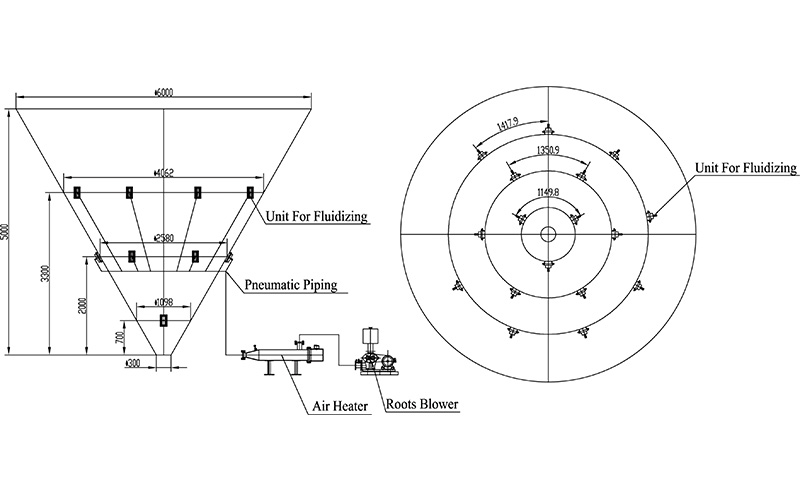

Ⅲ.Gasification discharge

Gasification device is an auxiliary part of storage silo, intermediate silo, ash hopper, flat bottom silo and hopper bottom silo. It is usually installed at the bottom of the material storage silo and the side of the ash hopper. When discharging, the heated compressed air will make the materials to be fluidized, to realize smooth discharging and avoid arching. It is generally composed of gasification plate formed by silicon carbide particle sintering, box shell and connecting flange.

Taking use of the large angle and height of the cone to make the material flow out naturally by gravity.

Advantages: the material flows out smoothly, and there is almost no residuum in the silo; the process is simple and easy to operate, no auxiliary discharge equipment is needed; fully making use of silo capacity without loss of storage capacity, and cone effectively increases silo capacity; the use of steel supports shorten construction period.

Half-cone gravity discharge

Large-diameter silo can adopt half-cone gravity discharge method to balance the discharge effect and construction cost.

Advantages: There is almost no residuum in the silo; no auxiliary discharge equipment is needed; the silo foundation is lower than the full-cone silo.

Ⅱ.Vibration discharge

Vibration discharge system vibrates the cone through the vibration motor so that the material is separated from the cone, and accelerates material flow to make material be discharged smoothly under gravity.

Advantages

1. The entire dischager cone vibrates to realize uniform vibration and discharging. and complete discharging of bulk materials;

2. All parts of the discharger which are in contact with the product can provide a stable material flow;

3. Low maintenance cost.

Ⅲ.Gasification discharge

Gasification device is an auxiliary part of storage silo, intermediate silo, ash hopper, flat bottom silo and hopper bottom silo. It is usually installed at the bottom of the material storage silo and the side of the ash hopper. When discharging, the heated compressed air will make the materials to be fluidized, to realize smooth discharging and avoid arching. It is generally composed of gasification plate formed by silicon carbide particle sintering, box shell and connecting flange.