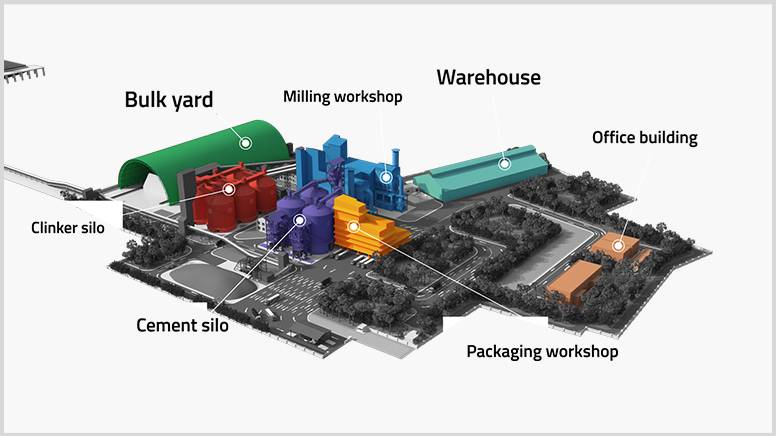

Silo Storage in Alumina Plant: Alumina undergoes calcination and cooling in a roasting furnace before being stored in an alumina silo via an air chute and bucket elevator. Aluminum is discharged from the silo into bulk trucks or bagged using a ton-packing machine, then transported to the electrolytic aluminum plant by car. Silo storage capacity in alumina plants typically ranges from 0.5 to 3 million tons.

Storage of Fresh Alumina in Electrolytic Plant: Electrolytic aluminum plants usually establish a warehouse for fresh alumina or a large silo for storing fresh alumina. Bulk material from tankers is conveyed into the fresh alumina silo, while bagged alumina is transferred into the silo via a belt conveyor after opening the bags. Fresh alumina is then pneumatically conveyed from the silo to the fresh alumina silo or the fluorine-containing alumina silo in the electrolytic workshop. The storage capacity of a large fresh alumina silo in an electrolytic plant is typically around 10,000 tons.

Electrolytic Fresh Alumina Silo, Fluorine-Containing Alumina Silo: Fresh alumina from the silo outlet is transported to the flue gas purification system through an air chute. After absorbing fluorine, it becomes fluorine-containing alumina and is transferred to the fluorine-containing alumina silo using an air chute and hoist. The fluorine-containing alumina is discharged from the silo and transported to each electrolytic tank for electrolysis via an air chute. The storage capacity of a single fresh alumina silo and fluorine-containing alumina silo near the electrolytic workshop is about 2000 tons.