Introduction

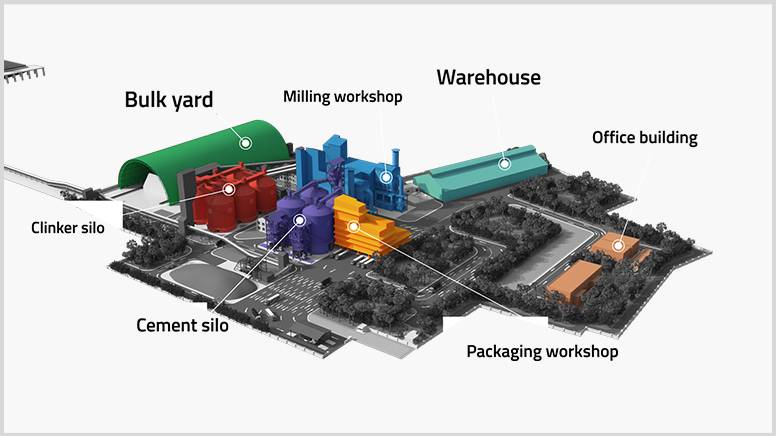

Steel silos have the characteristics of a large storage capacity, a short construction period, and low investment costs.

The steel silo has a large storage section and a good homogenization effect. With the extension of the storage period, the density of stored cement also increases, and the cement is essentially vacuum-sealed within the steel silo wall. The sealing effect and storage effect of steel silos are much better than those of brick and stone structure warehouses and bags. During feeding, the cement is continuously laid along the slope, so that the cement is layered and evenly distributed at different times.

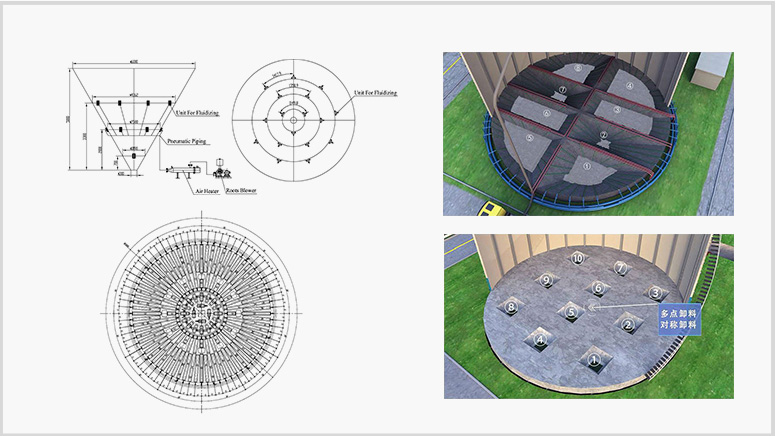

During discharging, the silo is alternately inflated in sequence through an inflatable fluidization system at the bottom of the silo, so that high-density sedimentary cement is fluidized and mixed with the air infiltration. Once it is in the fluidization state, it will enter into the distribution bin or bulk car through the discharge inlet by the discharge conveying pipe.

The steel silo has a large storage section and a good homogenization effect. With the extension of the storage period, the density of stored cement also increases, and the cement is essentially vacuum-sealed within the steel silo wall. The sealing effect and storage effect of steel silos are much better than those of brick and stone structure warehouses and bags. During feeding, the cement is continuously laid along the slope, so that the cement is layered and evenly distributed at different times.

During discharging, the silo is alternately inflated in sequence through an inflatable fluidization system at the bottom of the silo, so that high-density sedimentary cement is fluidized and mixed with the air infiltration. Once it is in the fluidization state, it will enter into the distribution bin or bulk car through the discharge inlet by the discharge conveying pipe.