-

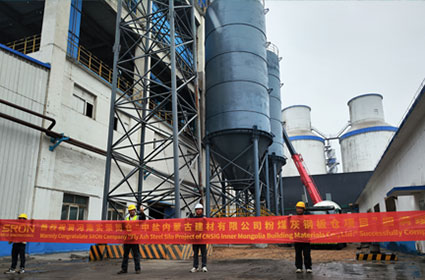

01

Sealed protection, fireproof and moisture-proof, safer

The petroleum coke steel silo adopts a fully enclosed structure, with rainproof top, moisture-proof bottom, and corrosion-resistant side walls, which can effectively isolate the impact of external water vapor and air on petroleum coke. Compared with the open-air stacking mode, it greatly reduces the risk of spontaneous combustion and agglomeration rate, ensuring the stability and availability of petroleum coke.

-

02

Dust-proof and environmentally friendly, helping green development

The petroleum coke steel silo can be equipped with dust recovery, negative pressure ventilation and other systems during design to effectively control the escape of petroleum coke dust and improve the on-site environment. Especially in the context of stricter environmental protection policies, steel silos provide solid support for enterprises to achieve green warehousing.

-

03

Small footprint, large capacity, saving land resources

The steel silo has a large storage capacity, with a single warehouse capacity ranging from several thousand tons to tens of thousands of tons, and an area far smaller than that of traditional bungalow warehouses or open-air yards, freeing up more available space for the factory area.

-

04

High degree of automation, improved operational efficiency

Modern petroleum coke steel silos are equipped with intelligent monitoring systems, which can monitor the temperature, humidity, material level and gas concentration in the silo in real time. Combined with the automatic feeding and unloading system, it can achieve unmanned and efficient operation, greatly reducing labor costs.

.jpg)

.jpg)

.jpg)

.jpg)