Pulverized coal, known for its dispersion, suspension, flammability, and ease of transportation, finds widespread use in power plant boilers, the cement industry, new pulverized coal industrial boilers, and other combustion equipment. Compared to raw coal, pulverized coal boasts a smaller particle size, a larger surface area, and a certain level of explosiveness.

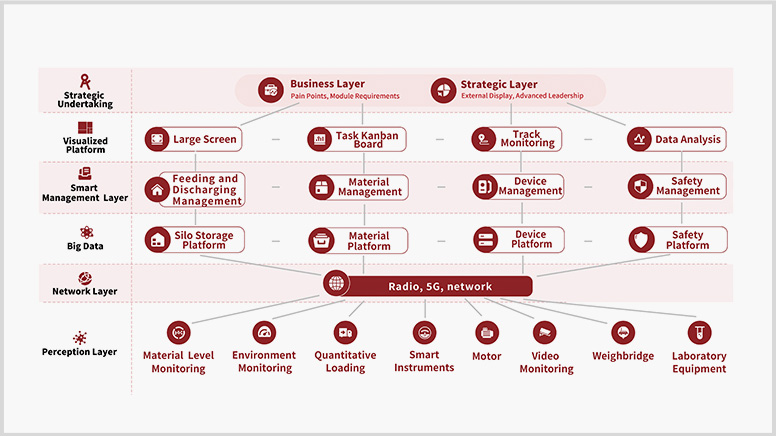

SRON meticulously considers anti-combustion and anti-explosion measures during the design process of the pulverized coal silo, an essential component for the preparation, storage, and supply of pulverized coal. The silo is outfitted with various safety detection devices, including an inert gas protection system, temperature regulation monitoring system, silo top explosion-proof valve system, and online monitoring systems for combustible gases such as CO, H2S, and CH4. These measures ensure the safe storage of pulverized coal.

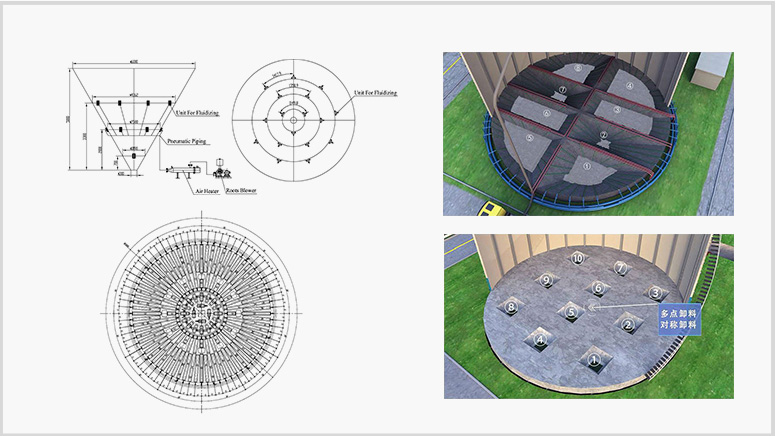

Furthermore, our company's pulverized coal steel silo boasts a high loading and unloading emptying rate, as well as excellent sealing, moisture resistance, and water seepage resistance performance, preventing core pulling during discharge.